Surface preparation

Contructions for galvanizing cannot have any closed spaces which may make it impossible to immerse or lead to a tear while dipping.

Each construction element should have suitable technological air vents facilitating the flow of zinc inside and outside, pressure releasing vents (when overlapping surfaces are bigger than 400 cm2) and vents (or handles) for proper suspension.

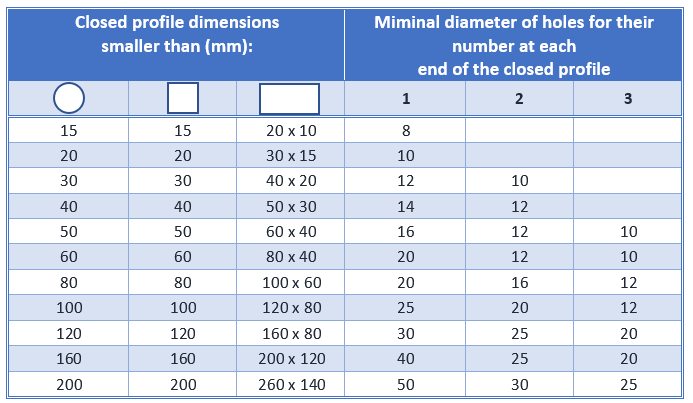

Minimal sizes of air vents depending on the cross section are presented below:

The table above specifies the size and number of vents to prepare on both ends of the profile depending on the size of the cross-section. The number refers to profiles not longer than 2.7 m., but when they exceed this length bigger vents need to be prepared.

Constructions should not possess any small crakcs or dents e.g. for weld seams because after galvanizing small amounts of flux and acid may drip resulting in poor quality coating.

Thermal interaction of the zinc bath releases inner stresses in elements which may lead to shape changes, especially visible on welded articles and elements.

| Download: | |

| Surface preparation (pdf) |  |