The choice of steel

Each type pf steel that fulfills the requirements of DIN 17100 and PN-88/H-84020 and PN-86/H-84018 norms can be hot-dip galvanized.

The quality of the galvanized surface (glaze, smoothness, thickness, adhesion etc.) is different and depends on the chemical composition; particulalry on the content of carbon (C), phosphorous (P) and silicon (P). The amount of carbon and silicon together should not exceed 0.5%.

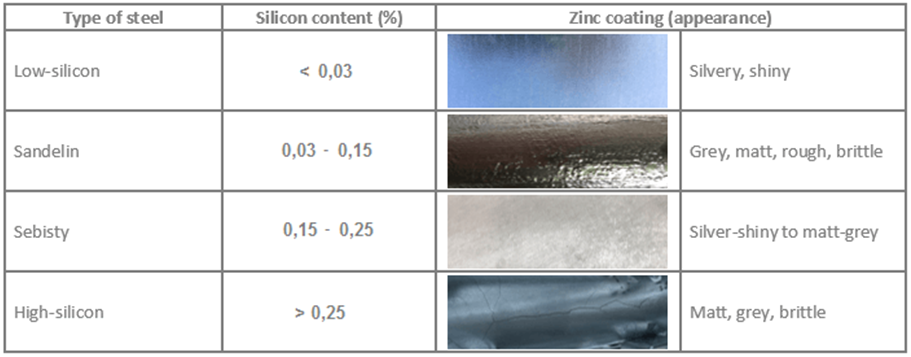

Sometimes in steels containing silicon, the iron-zinc reaction will be particularly intensive and the amount of iron-zinc alloy in the coating will be higher than usually. In extreme cases the zinc coating may be totally composed of the iron-zinc alloy. This phenomenon (also known as the 'Sandelin effect') is observed when the silicon content is between 0.03% and 0.14%, but also higher than 0.25%. In these cases the zinc coating is usually matt-grey, rough, uneven, brittle – sensitive to deformation and mechanicall damages.

Zinc coating features connected with the chemical content of steel are described in the PN-EN ISO 14713-2 norm. The zinc coating appearance on various types of steel is presented in the table below.